EOQ inventory model for perishable products under uncertainty

- Production Management

- Open access

- Published: 12 October 2020

- Volume 14 , pages 601–612, ( 2020 )

Cite this article

You have full access to this open access article

- R. Patriarca ORCID: orcid.org/0000-0001-5299-9993 1 ,

- G. Di Gravio 1 ,

- F. Costantino 1 &

- M. Tronci 1

8565 Accesses

14 Citations

1 Altmetric

Explore all metrics

Perishable products require accurate inventory control models as their effect on operations management can be critical. This assumption is particularly relevant in highly uncertain and dynamic markets, as for the ones generated by the pandemic era. This paper presents an inventory control model for perishable items with a demand rate variable over time, and dependent on the inventory rate. The model also considers the potential for backlogging and lost sales. Imperfect product quality is included, and deterioration is modelled as a time-dependent variable. The framework envisages the possibility to define variables affected by uncertainty in terms of probability distribution functions, which are then jointly managed via a Monte Carlo simulation. This paper is intended to provide an analytical formulation to deal with uncertainty and time-dependent inventory functions to be used for a variety of perishable products. The formulation is designed to support decision-making for the identification of the optimal order quantity. A numerical example exemplifies the outcomes of the paper and provides a cost-based sensitivity analysis to understand the role of main parameters.

Similar content being viewed by others

Optimization of Inventory Management: A Literature Review

RETRACTED ARTICLE: A mathematical model to investigate the interactive effects of important economic factors on the behaviors of retailers

Analysis of a manufacturing queueing system using bi-level randomized policy

Avoid common mistakes on your manuscript.

1 Introduction

The economic order quantity (EOQ) is an inventory control model largely accepted in industrial operations management, since its introduction in the earliest decades of the twentieth century [ 1 ]. However, the original model presents several unrealistic assumptions that motivated scholars to study the EOQ under real-life scenarios [ 2 ]. One of the more investigated area refers to products that suffer of a short lifecycle. This vast literature becomes particularly relevant in current days for the identification of the control models to be adopted for sustainable inventory and production management. Besides traditional food and beverage products, more critical items refer indeed to medical supplies such as surgical masks, reagents, swabs, pads that in the pandemic era require even more accurate ordering and replenishment strategies.

From a production management perspective, such products are currently critical, due to the large size of demand required by societal needs and subjected to public purchasing with urgent timing. The batch size becomes a crucial variable considering the difficulties arising in product transferring between suppliers and customers. Products may also suffer from possible damages during deliveries, reducing their quality level. The highly dynamic current market also pushes competition over quality, jeopardizing products’ integrity, as well as facilitating products’ deterioration. Furthermore, since in real settings all these features are largely affected by uncertainty, deterministic inventory models become no more effective for the minimization of respective management costs.

An opportunity emerges here to further investigate and refine an EOQ model in light of the features required to support a sustainable production management for products that are strategic during a pandemic. It thus becomes necessary to ensure that operations rely on optimization of parameters referred to reduced quality of products over time, and to the deterioration effects on customers’ purchasing interest. In addition, deterioration may also yield waste, which has to be disposed, generating not-negligible disposal cost.

On these assumptions, this paper contributes to the field of production engineering research by proposing a new model that can take into account costs related to perishable products, along with the uncertainty of demand and quality level, and the associated effect on customers, i.e. backordering or lost sales. Even though this document presents an integrated formulation for modelling the features of pandemic related items, the model has been built to provide an analytic formulation easily extensible to a large set of perishable products (e.g. pharmaceutical, food and beverages).

The remainder of the paper is organized as follows. Section 2 provides a literature review on more relevant EOQ models for perishable products. Section 3 details the proposed integrated analytical model, which is then exploited via a numerical Monte Carlo simulation in Sect. 4 . Finally, the conclusions summarize the outcome of this work and the potential for future research.

2 Literature review

Products can lose their value during storage due to: (1) obsolescence, i.e. losing value over time due to technological changes or substitutes entering the market; (2) deterioration, i.e. the change or decay of the physical characteristics of a product which results in a reduction in the usefulness. Products affected by deterioration can be classified as perishable, with a known lifetime and expiry date, and decaying, with unknown lifetime. The ones characterized by high deterioration rate can generate stock-out, lost sales and disposal costs [ 3 ].

In EOQ models for perishable products, each batch presents a constant or variable rate of deterioration that can move compliant products to defective, even after their receipt in the factory. In recent years, an instantaneous deterioration at a constant rate has been proposed with a demand linearly increasing in time, assuming full recovery of backorder after replenishment [ 4 ]. Karthikeyan and Santhi [ 5 ] consider the demand as a cubic function over time, for which stock-out is not allowed but products have a salvage value. Khurana and Chaudhary [ 6 ] follow a demand depending on both the level of available stock and price, and then develop two models with a different backlogging rate, i.e. constant or depending on the waiting time until the arrival of the next batch. Mahapatra [ 7 ] study a model for high reliability products: buyers are inclined to acquire high-quality products to reduce maintenance costs and the possibility of failure, stock-out is partially managed in backorder. Kumar [ 8 ] examines the effect of a time-dependent linear demand in case of positive stock level, and a constant demand during stock-out. Tripathi [ 9 ] develops a model for seasonal food products with quadratic demand over time, and possible stock-out with no lost sale. Shaikh [ 10 ] proposes a model with temporary discount on the purchase unit cost, where the demand function depends on the price and the level of available stock, while during stock-out the demand depends only on the price of the product.

A further specialization for perishable products provides a constant rate with non-instantaneous deterioration, starting after a certain amount of time [ 11 ]. In particular, Tat et al. [ 12 ] develop a model for a two-tier supply chain, allowing stock-out. Palanivel and Uthayakumar [ 13 ] consider the demand function dependent on price and advertising, assessing the effect of inflation and the time value of money.

In reality, a constant rate of deterioration rarely occurs as most products deteriorate more as time passes. Mishra [ 14 ] present the demand as a linear function over time when the stock level is positive, becoming constant during stock-out, and backlogging rate inversely proportional to the lead time of the next replenishment. With the same assumptions, Singh [ 15 ] develop a model with a time-dependent deterioration rate and no stock-out allowed, where the demand rate changes over time, i.e. constant over time before deterioration, and linear in time after deterioration starts.

Other examples of a variable rate consider the adoption of Weibull distribution. For instantaneous deterioration, a two-parameter Weibull distribution is proposed by: Rajoria et al. [ 16 ] (with both time-dependent demand and backlogging rate, considering inflation), Sharma et al. [ 17 ] (price and expiry-date dependent demand and two backlogging rates, constant or variable) and Pervin et al. [ 18 ] (linear demand over time and partial backorder). A two-parameter Weibull distribution can be used if the deterioration rate is decreasing and the initial value is very high or if it is increasing with an initial value approximately null. Otherwise, (e.g.) when the deterioration starts after a certain period, a three-parameter Weibull distribution is required: Sanni and Chukwu [ 19 ] develop a model with time-dependent quadratic demand and partial backorder; Singh et al. [ 20 ] develop a model for a new seasonal product with time-dependent ramp demand, possible stock-out and full recovery. Finally, Palanivel and Uthayakumar [ 21 ] present a model where the demand is a function of price, advertising, and inflation, admitting stock-outs, and partial backlogging with a rate depending on the lead time until the arrival of the next batch. The deterioration starts only after a certain period with a rate represented by three continuous probability distributions: uniform, triangular, and beta.

From the analysis of this literature, it emerges the need to develop a model which is able to represent the features of a complex scenario such as the one present during a pandemic, via an analytic formulation which is also subjected to uncertainty. On these bases, this paper presents an integrated EOQ inventory control model for perishable products, subject to variable defectiveness checked during quality control and time-dependent deterioration, which can cause both backorder and lost sale. The proposed paper indeed integrates different analytical formulations discussed individually in previous research and adopts Monte Carlo simulation to solve the resulting optimization problem. In addition to the integrated analytical nature of this work (whose detail choices have been discussed in detail in Sect. 3), the contribution proposed here is intended to support decision-making with a clear representation of uncertainty effects.

3 Analytical model

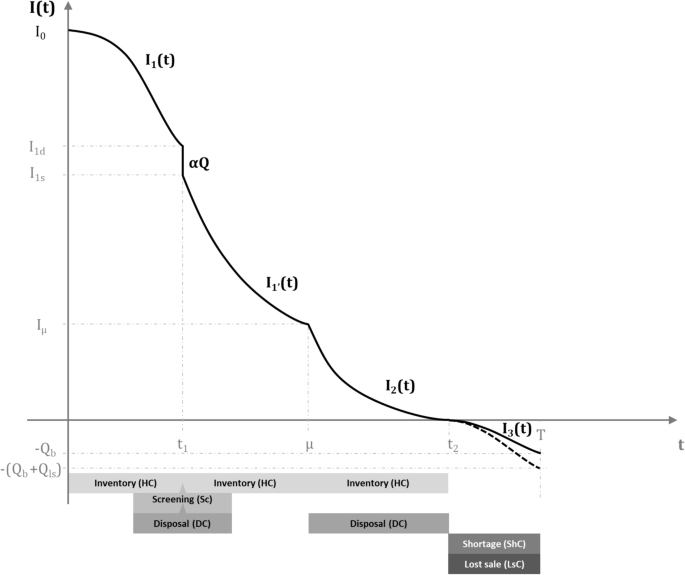

The analytical formulation models an economic order quantity problem for a single perishable item. The deterioration of the products determines the likely possibility of generating an anticipated stock-out situation [ 22 ], which is considered in a partial backlogging scenario. The deterioration rate starts after a specific known time moment μ and is a random variable [ 13 ]. No substitution or repair of deteriorated products is allowed during the re-ordering period. In practical terms, the total costs referred to this situation are represented by a combination of holding cost (cost due to the materials stocked in the warehouse), screening cost (cost to be paid for checking the quality of products), disposal costs (cots required to dispose the products that do not satisfy the quality level after the initial screening, or when the deterioration starts); the shortage cost (cost to be paid when the demand is not matching the remaining inventory), and the lost sale costs (cost paid in case there is left in the inventory at the moment of re-ordering). Figure 1 summarizes conceptually the different cost components, as a basis for the subsequent mathematical formulation.

Conceptual overview of the stock level in a period T

Additional specific features of the model can be summarized as follows:

Replenishment occurs instantaneously

The demand is stock-dependent: a quadratic function in standard situations [ 19 ], and constant influenced by \({B}_{r}\left(t\right)\) during the stock-out period [ 14 ].

DETERIORATION. The products can be sold until T, which corresponds to the expiry date of the product in question, assumed to be equal to the inventory ordering cycle. Products left in stock after T constitute lost sales, since they do not respect the requirements of the customer.

BACKLOGGING. The backlogging rate \({B}_{r}\left(t\right)\) , i.e. the portion of demand to be satisfied in backorder, is variable and is dependent on the length of the waiting time for the next replenishment: a longer backlogging rate would imply a smaller portion of customers would accept backlogging at time t. This situation is described in case of negative inventory, as follows [ 15 ]:

where \((T-t)\) is the remaining time before next replenishment, and \(\varphi >0\) is a factor inversely representing the backorder rate imposed by the company: \(\varphi =0\) implies a full backorder management \({B}_{r}\left(t\right)=1\) , with progressively lower backlogging rates for larger values of \(\varphi\) .

DEFECTIVENESS. Every order includes a percentage of defective products α , which is a random variable whose probability density function f(α) is uniform and known [ 23 ]. Screening is conducted in the interval \(\left[0,{t}_{1}\right]\) with a screening frequency λ . The screening process is assumed to be perfect: no mis-classified products are possible. All defective units are removed contemporarily from the inventory at the end of the screening process, i.e. \({t}_{1}\) . The screening rate is sufficiently large to ensure that a number of products larger than the demand is screened in \(\left[0,{t}_{1}\right]\) . This assumption is acceptable since the screening process takes only little time, especially considering modern automated technologies for screening. The defective items are independent of deterioration \({(t}_{1}< \mu )\) . A constraint on \(\alpha\) is needed to avoid stockout during the screening process:

HOLDING. The holding cost per unit is proportional to both the storage time and consists of two components: a constant part ( g ) and another part linearly increasing with the storage time ( h ). The holding cost function is \(H\left(t\right)=\left(g+ht\right)\) . This assumption motivates the potential benefits of larger holding cost to compensate the deterioration process increasing over time [ 10 ].

The stock level in \(t=0\) corresponds to the maximum level of inventory \(I\left(t=0\right)={I}_{0}\) . In the time interval \(\left[0,\mu \right]\) the stock level decreases following the demand D ( t ):

where imposing \({I}_{1}\left(0\right)={I}_{0}\) , and considering and \({t}_{1}\) as a function of the screening rate \(\lambda\) , \({t}_{1} =\frac{Q}{\lambda }\) :

The inventory level including defective products is \({I}_{1d}\left({t}_{1}\right)\) :

Since the amount of defective items \({t}_{1}\) is equal to αQ [ 23 ], the actual level of usable products is:

Consequently, the stock level in \(\left[{t}_{1},\mu \right]\) can be modelled as:

where \({I}_{{1}^{{{\prime}}}}\left(\mu \right)={I}_{\mu }\) .

Since deterioration starts at μ , the inventory level in \(\left[\mu ,{t}_{2}\right]\) is:

This differential equation can be solved imposing \({I}_{2}\left(\mu \right)={I}_{\mu }\) and \({I}_{2}\left({t}_{2}\right)=0\) [ 9 ]:

Considering \({I}_{{1}^{{\prime}}}\left(\mu \right)={I}_{2}\left(\mu \right)\) :

where, after simple mathematical manipulations and considering \(Q={I}_{0}+{Q}_{b}\) :

After \({t}_{2}\) , a partial backorder phenomenon is activating [ 14 ]:

where, the condition \({I}_{3}\left({t}_{2}\right)=0\) is needed to ensure the backorder condition, starting after \({t}_{2}\) :

And consequently, the value of \({I}_{3}\left(t\right)\) [ 15 ]:

Here, \({Q}_{b}\) is obtained for \(t=T\) , i.e. the maximum amount of demand backlogged per cycle:

Hence \(Q\) :

Then the respective inventory management costs can be calculated, as for the following formulas:

Screening Cost:

Holding Cost:

Full details on analytical characteristics of \({HC}_{1},{HC}_{2}, {\text{and}} \ {HC}_{3}\) are presented in the Appendix.

Disposal Cost:

where \({Q}_{d}\) represents the amount of deteriorated products in \(\left[\mu ,{t}_{2}\right]\) :

Shortage cost [ 14 ]:

Lost sales cost [ 14 ]:

Finally, the total cost is the sum of the previous elements:

4 Numerical example

The complicated structure of the proposed formulation does not allow an efficient analytical closed-form solution, especially when considering the probabilistic nature of the mentioned variables. As such, the problem has been solved via a Monte Carlo simulation model, which ensures a relatively simple, flexible, and computationally efficient analysis. Each Monte Carlo simulation consisted of 5000 iterations [ 24 ], relying on Mersenne twister, an efficient pseudo-random numbers generating algorithm.

4.1 Base scenario

The model has been then validated with the data presented in Table 1 . Besides a base scenario which summarizes the values representative of plausible settings, a sensitivity analysis has been performed to study the impact of main variables on the order quantity and respective total cost. The numerical values assigned in the base scenario have been based on previous literature on perishable products (e.g. [ 9 , 10 , 22 , 23 ]) as well as some manipulated data of a company dealing with ordering of products for pandemic. These values serve only for demonstration purposes. Considering indeed that the contribution of this research consists of proposing a formulation suitable for different products, it has been decided to provide a sensitivity analysis in order to further prove the validity and robustness of the results with different input values.

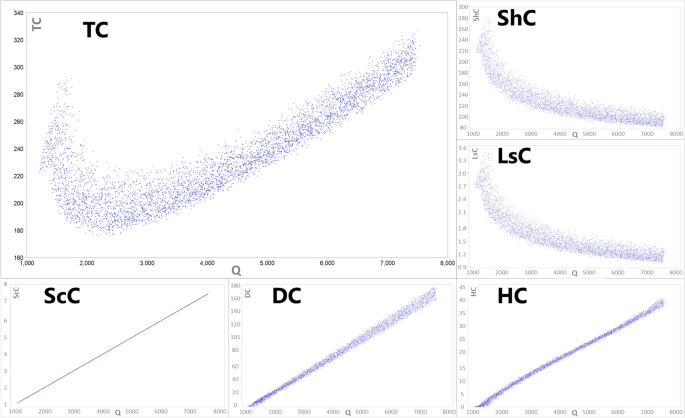

From the analysis of results presented in Fig. 2 , it clearly appears the major contribution to the total cost (TC) played by the shortage cots (ShC) and the disposal cost (DC), which shows a similar pattern of the holding cost (HC). This probabilistic analysis confirms the trade-off to be set to ensure an economical order strategy.

Cost vs quantity functions in the base scenario

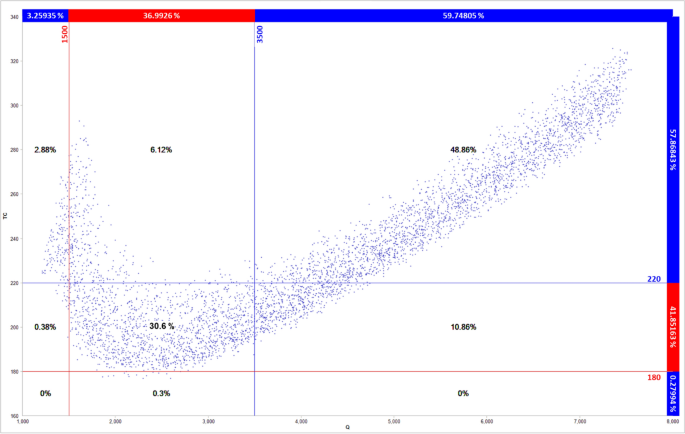

This analysis can be used as a support for decision-making under uncertainty, as shown in Fig. 3 . Besides the inherent uncertainty on the demand value, there could be randomness in any of the proposed variable. Therefore, a certain threshold on the total cost (vertical axis) can be set to understand the feasibility of an imposed budget constraint. The decision-maker can thus establish a certain range of Q to assess the effect on total cost (or of course, on any other cost).

Example of cost/quantity parametric decision-making process for the base scenario

For example, within the range of Q (1500, 3500), the total cost will exceed the budget constraint (TC = 220) only for about 6%. A larger or shorter range can be proposed, depending on exogenous variables (e.g. supplier’s constraint on ordering quantity).

4.2 Sensitivity analysis

Three sensitivity analyses have been performed to study the impact of the defect rate α ), deterioration ( \(\uptheta\) ), and the backlogging parameter ( φ ). Results show consistency with potential real scenarios, as detailed in the following figures (see Figs. 4 , 5 , 6 ).

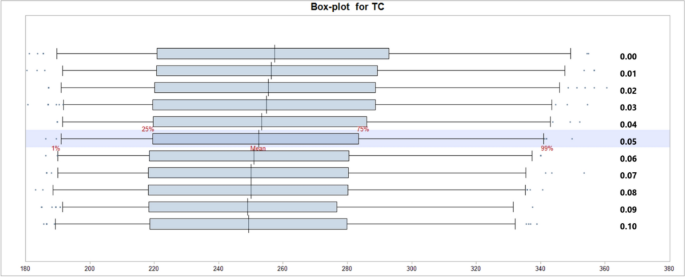

Box-plot of total cost, with changing α , highlighted item corresponds to α = 0.05

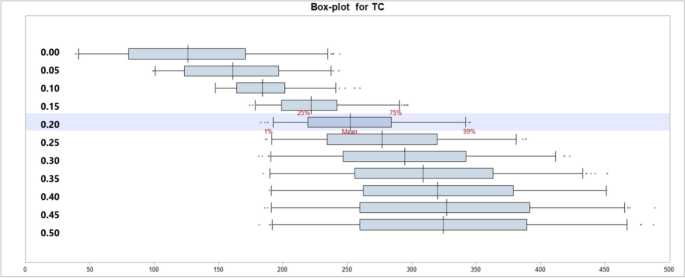

Box-plot of total cost, with changing \(\theta\) , highlighted item corresponds to \(\theta\) =0.20

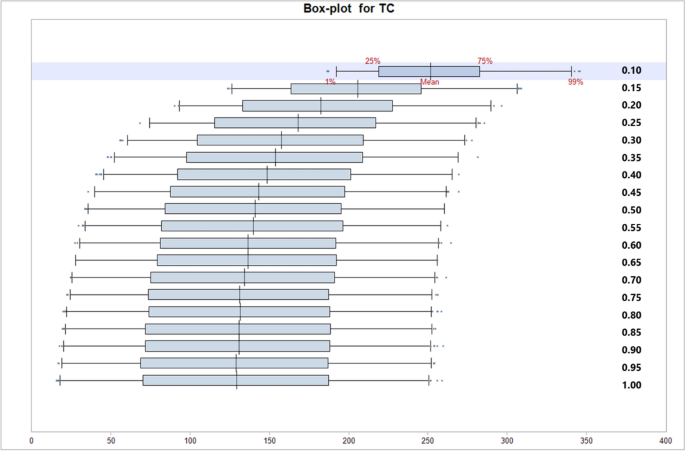

Box-plot of total cost, with changing φ , highlighted item corresponds to φ = 0.10

4.2.1 Defective products ratio

The sensitivity analysis on the defective product ratio shows that there is no significant contribution to the total cost, while deviations can be ascribed to the random nature of the other variables: α has been set ranging from 0 (no defect) to 0.10 (10 percentage of defective products during screening), as shown in Fig. 4 .

4.2.2 Deterioration rate

About the deterioration rate, as it increases, there is a significant increase in the required lot size (Q), and associated costs, as shown in Fig. 5 . This increment is largely representative of the increment in the shortage costs (ShC) and the lost sale costs (LsC), while negligible variations are experienced in the holding cost (HC). The sensitivity analysis is here stopped at \(\uptheta\) =0.50, representing a reasonable boundary condition for deterioration rate in line with previous research which usually reports a value of \(\uptheta\) never exceeding 0.3 [ 9 , 10 , 22 ].

4.2.3 Backlogging parameter

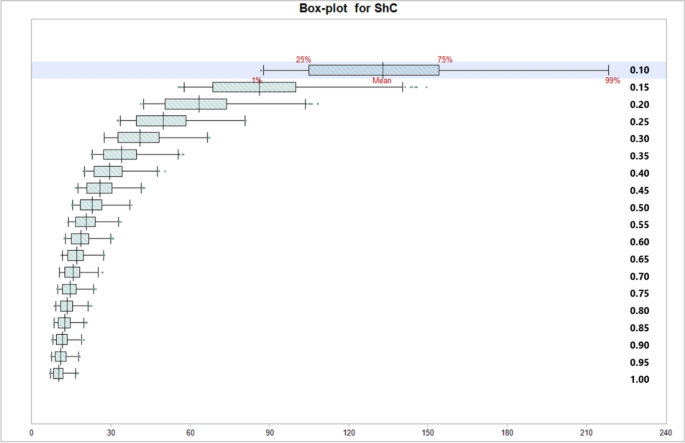

The backlogging parameter φ shows a non-negligible effect on the total cost. In the range from 0.1 to 1, the total cost presents a decrease up to φ = 0.70. As expected, the tendency is largely due to the effect on the shortage costs (ShC) which progressively are affected by a reduced randomness, due to the increased acceptance of the backlogging (see Figs. 6 , 7 ). Minor effects are observable in lost sale costs (LsC), while negligible effects are presented in the other components of the cost function.

Box-plot of shortage cost, with changing φ , highlighted item corresponds to φ = 0.10

5 Conclusions

Current competitiveness requires dedicated strategies to deal with the uncertainty of market in highly dynamic settings. The paper presents an EOQ model which integrates a variety of products features to extend the credibility of the standard formulation also to cases affected by uncertainty, via a Monte Carlo simulation. The model allows the identification of advantageous quantity ranges for orders and the respective economic risk profile.

Furthermore, in more general terms, as proved by the cost sensitivity analysis, the model allows the isolation of the most significant variable dependencies (i.e. backlogging parameter, deterioration coefficient), supporting a parametric EOQ assessment.

Future research directions may include additional models of the deterioration process, i.e. other probability distribution functions suitable to represent the behaviours of specific products over time. Additionally, the framework could be enhanced to encompass other operations management aspects, (e.g.) permissible delay in payments, quantity discounts flexible re-ordering intervals. Considering the positive results obtained via the proposed Monte Carlo simulation in combination with the provided analytical framework, this research confirms the usefulness of the proposed approach as decision-making support tools able to ensure an effective inventory management for critical products.

The proposed framework can be adopted for a large variety of deteriorating items, whose market presence can also be indirectly affected by the pandemic scenario itself. In this sense, a proper setting of the input, as well as the decisional, variables allows a flexible optimization process. The framework remains also extensible to post-pandemic scenarios for traditional deteriorating products (e.g. milk, fruits, vegetables, among others), whose uncertainty is expected to be limited in (e.g.) the demand variability over time. In these cases, the decisional variables may also be adjusted to reflect proper risk appetite of the decision-makers or even be iteratively defined to run what-if scenarios.

Abbreviations

Demand rate in D ( t = 0) \((a>0)\)

Demand rate coefficient \((b\ne 0)\)

Unit backorder cost

Demand rate coefficient \((c\ne 0)\)

{\rm unit} deteriorating cost

Constant coefficient of the holding cost

Variable coefficient of the holding cost

Unit lost sale cost

Unit screening cost

Screening process starting time

Stock-out starting time

Percentage of defective products

Deterioration rate

Screening rate

Deterioration process starting time

Backlogging parameter \((\varphi >0)\)

Backlogging rate

Demand rate

Demand rate when inventory is null

Holding cost function

Maximum inventory level

Inventory level in the time interval [0, t 1 ]

Inventory level in the time interval [t 1 , μ]

Inventory level in the time interval [μ, t 2 ]

Inventory level in the time interval [t 2 , T]

Inventory level in t 1, considering defective products

Inventory level in t 1, without defective products

Inventory level in μ

Ordered quantity

Maximum backorder quantity

Inventory cycle length

Osteryoung JS, Nosari E, McCarty DE, Reinhart WJ (1986) Use of the EOQ model for inventory analysis. Prod Invent Manag 27:39–46. https://doi.org/10.5555/15262.15268

Article Google Scholar

Salameh MK, Jaber MY (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64:59–64. https://doi.org/10.1016/S0925-5273(99)00044-4

Moussawi-Haidar L, Salameh M, Nasr W (2014) Effect of deterioration on the instantaneous replenishment model with imperfect quality items. Appl Math Model 38:5956–5966. https://doi.org/10.1016/j.apm.2014.05.003

Article MathSciNet MATH Google Scholar

Tripathi RP, Uniyal AK (2015) Economic order quantity model for deteriorating items with time-dependent demand rate under time varying shortages. Int J Math Oper Res 7:706–719. https://doi.org/10.1504/IJMOR.2015.072278

Karthikeyan K, Santhi G (2015) An inventory model for constant deteriorating items with cubic demand and salvage value. Int J Appl Eng Res 10:3723–3728

Google Scholar

Khurana D, Chaudhary RR (2016) Optimal pricing and ordering policy for deteriorating items with price and stock dependent demand and partial backlogging. Uncertain Supply Chain Manag 4:307–318. https://doi.org/10.5267/j.uscm.2016.3.004

Mahapatra GS, Adak S, Mandal TK, Pal S (2017) Inventory model for deteriorating items with time and reliability dependent demand and partial backorder. Int J Oper Res 29:344–359. https://doi.org/10.1504/IJOR.2017.084340

Article MathSciNet Google Scholar

Kumar P (2019) Inventory optimization model for quadratic increasing holding cost and linearly increasing deterministic demand. Int J Recent Technol Eng 7:1999–2004

Tripathi RP (2019) Innovation of economic order quantity (EOQ) model for deteriorating items with time-linked quadratic demand under non-decreasing shortages. Int J Appl Comput Math 5:1–13. https://doi.org/10.1007/s40819-019-0708-x

Shaikh AA, Khan MAA, Panda GC, Konstantaras I (2019) Price discount facility in an EOQ model for deteriorating items with stock-dependent demand and partial backlogging. Int Trans Oper Res 26:1365–1395. https://doi.org/10.1111/itor.12632

Ahmad B, Benkherouf L (2018) Economic-order-type inventory models for non-instantaneous deteriorating items and backlogging. RAIRO Oper Res 52:895–901. https://doi.org/10.1051/ro/2018010

Tat R, Taleizadeh AA, Esmaeili M (2015) Developing economic order quantity model for non-instantaneous deteriorating items in vendor-managed inventory (VMI) system. Int J Syst Sci 46:1257–1268. https://doi.org/10.1080/00207721.2013.815827

Article MATH Google Scholar

Palanivel M, Uthayakumar R (2015) Finite horizon EOQ model for non-instantaneous deteriorating items with price and advertisement dependent demand and partial backlogging under inflation. Int J Syst Sci 46:1762–1773. https://doi.org/10.1080/00207721.2013.835001

Mishra PJ, Singh T, Pattanayak H (2016) An EOQ inventory model for deteriorating items with linear demand, salvage value and partial backlogging. Int J Appl Eng Res 11:6479–6484

Singh T, Mishra PJ, Pattanayak H (2017) An optimal policy for deteriorating items with time-proportional deterioration rate and constant and time-dependent linear demand rate. J Ind Eng Int 13:455–463. https://doi.org/10.1007/s40092-017-0198-6

Rajoria YK, Saini S, Singh SR (2015) EOQ model for decaying items with power demand, partial backlogging and inflation. Int J Appl Eng Res 10:22861–22874

Sharma S, Singh S, Singh SR (2018) An inventory model for deteriorating items with expiry date and time varying holding cost. Int J Procure Manag 11:650–666. https://doi.org/10.1504/IJPM.2018.094357

Pervin M, Roy SK, Weber G-W (2018) Analysis of inventory control model with shortage under time-dependent demand and time-varying holding cost including stochastic deterioration. Ann Oper Res 260:437–460. https://doi.org/10.1007/s10479-016-2355-5

Sanni SS, Chukwu WIE (2016) An inventory model with three-parameter weibull deterioration, quadratic demand rate and shortages. Am J Math Manag Sci 35:159–170. https://doi.org/10.1080/01966324.2015.1126697

Singh T, Mishra PJ, Pattanayak H (2018) An EOQ inventory model for deteriorating items with time-dependent deterioration rate, ramp-type demand rate and shortages. Int J Math Oper Res 12:423–437. https://doi.org/10.1504/IJMOR.2018.092103

Palanivel M, Uthayakumar R (2016) Finite horizon EOQ model for non-instantaneous deteriorating items with probabilistic deterioration and partial backlogging under inflation. Int J Math Oper Res 8:449–476. https://doi.org/10.1504/IJMOR.2016.076784

Mahata P, Mahata GC, De SK (2020) An economic order quantity model under two-level partial trade credit for time varying deteriorating items. Int J Syst Sci Oper Logist 7:1–17. https://doi.org/10.1080/23302674.2018.1473526

Jaggi CK, Goel SK, Mittal M (2011) Economic order quantity model for deteriorating items with imperfect quality and permissible delay on payment. Int J Ind Eng Comput 2:237–248. https://doi.org/10.5267/j.ijiec.2010.07.003

Di Gravio G, Mancini M, Patriarca R, Costantino F (2015) Overall safety performance of air traffic management system: forecasting and monitoring. Saf Sci. https://doi.org/10.1016/j.ssci.2014.10.003

Download references

Open access funding provided by Università degli Studi di Roma La Sapienza within the CRUI-CARE Agreement.

Author information

Authors and affiliations.

Department of Mechanical and Aerospace Engineering, Sapienza University of Rome, Via Eudossiana, 18, 00184, Rome, Italy

R. Patriarca, G. Di Gravio, F. Costantino & M. Tronci

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to R. Patriarca .

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Patriarca, R., Di Gravio, G., Costantino, F. et al. EOQ inventory model for perishable products under uncertainty. Prod. Eng. Res. Devel. 14 , 601–612 (2020). https://doi.org/10.1007/s11740-020-00986-5

Download citation

Received : 29 May 2020

Accepted : 22 September 2020

Published : 12 October 2020

Issue Date : December 2020

DOI : https://doi.org/10.1007/s11740-020-00986-5

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Inventory management

- Deteriorated products

- Defective products

- Disposal cost

- Find a journal

- Publish with us

- Track your research

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Springer Nature - PMC COVID-19 Collection

Internet of things for perishable inventory management systems: an application and managerial insights for micro, small and medium enterprises

Pratik maheshwari.

1 National Institute of Industrial Engineering, Mumbai, India

Sachin Kamble

2 EDHEC Business School, Roubaix, France

Ashok Pundir

Amine belhadi.

3 Cadi Ayyad University, Marrakech, Morocco

Nelson Oly Ndubisi

4 College of Business and Economics, Qatar University, Doha, Qatar

Sunil Tiwari

5 ESSCA School of Management, Lyon, France

Micro, Small, and Medium Enterprises (MSMEs) operating in the food retailing sector encounter two main concerns with respect to their perishable inventory management system, i.e., the product’s shelf life and investment in warehouse monitoring systems. New technologies like the Internet of Things (IoT), automated inventory control platforms, and automatic storage and retrieval systems offer effective solutions to these issues. However, MSMEs are reluctant to adopt these technologies due to their prior perception of higher implementation costs and the expected benefits. The present study aims to optimize IoT implementation in MSMEs’ inventory management systems and to provide tangible proof of its feasibility and usefulness. In so doing, we propose a mathematical model and analyze the impact of IoT through two case studies. The model provides a cost–benefit analysis of IoT investments that aim to increase products’ shelf life. We adopted the fractional program method, solved by particle swarm optimization on MATLAB software. The findings demonstrate the positive correlation between adopting IoT and reduced inventory costs supporting IoT deployment for improved perishability performance in MSMEs. The study offers several insights and practical guidelines in considering IoT deployment in MSMEs.

Introduction

The dynamic behavior of customers, cut-throat competition, rapid growth in technology, and globalization have all imposed critical challenges on maintaining acceptable quality and optimal inventory levels in retail industries and warehouse sectors (Gupta et al., 2020 ). For practitioners, monitoring and control aspects of warehouse management are vital tasks that include analyzing various parameters such as enzymes, micro-organisms, temperature, and humidity which constitute serious challenges when managing perishable items (Bakker et al., 2012 ; Gupta et al., 2020 ; Pérez et al., 2019 ). In recent years, issues concerning the management and warehousing of perishable items have gained increased interest among researchers and practitioners (Gupta et al., 2020 ; Tiwari et al., 2017 ). Perishable items are characterized by shorter shelf life and require meticulous warehousing and management systems to avoid spoilage, maintain their availability, and ensure revenue generation for the whole business (Gupta et al., 2020 ; Patel & Gor, 2019 ). Perishable warehouse and inventory management systems concern several items (e.g., storage of pharmaceuticals, fruit, vegetables, grains, and volatile liquids).

Previous studies have argued that most food companies, particularly Micro, Small, and Medium Enterprises (MSMEs), view higher perishability rates as the main reason for declining revenue generation (Kamble et al., 2020b ; Zhu et al., 2021 ). MSMEs face enormous financial and organizational challenges in warehouse facility management (Belhadi et al., 2018 ), involving significant national economic losses. According to Yang et al. ( 2019 ), 30% of perishable items handled by MSMEs deteriorate due to improper handling and lack of facilities (e.g., China loses 43 billion US$ per year). In the context of MSMEs, deterioration is a widespread phenomenon in perishable items, leading to wastage of around 20% of all food production (Li et al., 2019 ). In a developing country like India, improper maintenance of perishable items by MSMEs led to annual losses of 40%, at a value of over 14 billion US$ a year. The main causes of such losses in MSMEs are poor storage systems, outdated storage facilities, improper handling of units, poor collaboration, and lack of infrastructure (Sharon et al., 2014 ). Sharon et al. ( 2014 ) found that inadequate and outdated warehouse facilities in MSMEs generated 6% of post-harvest losses. Insufficient storage and non-optimized handling depend on various factors like lack of communication, lack of logistic facilities, and inadequate strategies between supply chain partners.

To maintain product quality and the smooth flow of inventories, the public and private sectors have introduced many initiatives to develop warehouse facilities via high-tech infrastructures. For instance, the National Horticulture Mission (NHM), India, estimates that over US$ 8.5 billion was invested in the warehouse sector, and 101 high-tech cold storage projects were approved in 2019. The recent literature has extensively recommended adopting advanced technologies such as the internet of things (IoT) for perishable inventory management (Čolaković et al., 2020 ; Kamble et al., 2018b ; Moeuf et al., 2018 ; Pundir et al., 2019a ; Salunkhe & Nerkar, 2017 ). According to Kamble et al. ( 2019 ), IoT substantially improves the product picking process, communication between processes and reduces product spoilage. It thus appears that IoT has great potential to help food-related MSMEs to control food product quality, reduce waste by enhancing food shelf life, manage operating conditions equipment, and reduce energy consumption (Kamble et al., 2018b , 2020b ).

Despite the vast potential of IoT in the food retail supply chain (Kamble et al., 2019 ; Pundir et al., 2019b ; Sharon et al., 2014 ), the adoption of IoT for perishable or Non-Instantaneous Deteriorating Items (NIDIs) inventory management is still in the nascent stage, especially for MSMEs (Hansen & Bøgh, 2021 ). Many financial, organizational, and technical challenges hinder IoT investment in MSMEs (Hansen & Bøgh, 2021 ; Huang et al., 2020 ; Kamble et al., 2018b ). A study by Kamble et al. ( 2019 ), for instance, argued that the apparent lack of successful IoT initiatives is mainly due to the perception of high operating and implementation costs. However, no validation studies are available in the present literature. Hence, there is an urgent need to conduct additional studies to validate the benefits of IoT and convince MSME managers/owners. The current research focuses on IoT implementation in MSMEs in the NIDIs context. A mathematical model with IoT investment for profit maximization in a single warehouse environment is developed and validated using a case study.

The remainder of the paper is organized as follows. Section 2 presents a literature review on our study’s three main topics, i.e., IoT, MSMEs, and perishable items warehousing. Section 3 illustrates the IoT-based model for perishable items inventory management in the context of MSMEs. Section 4 presents the model formulation, while Sect. 5 demonstrates the model’s application and offers insights for discussion and implications. Finally, Sect. 6 concludes the paper with the limitations and the future research agenda.

Literature background

Internet of things implementation in msmes.

IoT refers to an object-space connected network wherein real-time communication between physical and cyber systems is established. It includes several information and communication-based technologies such as computers, mobile technologies, smart sensors, and analytics platforms (Hansen & Bøgh, 2021 ; Moeuf et al., 2018 ). IoT is based on mutual intelligent relationship formation through sensing, information processing, and networking among objects with minimum human intervention.

The implications of IoT are not well developed among MSMEs, and very few successful cases are available in the literature. This means that MSMEs’ real benefits and the requirements for implementing IoT are not fully known (Moeuf et al., 2018 ). Theoretically, several studies have asserted that IoT might be extremely useful for smaller companies. For instance, (Moeuf et al., 2018 ) found that 90% of experts agreed that IoT is a crucial Industry 4.0 technology that MSMEs should leverage to generate exploitable data. Hansen and Bøgh ( 2021 ) posit that IoT would shape the future of operation management in MSMEs and has considerable potential to ensure their survival and competitiveness. This is further supported by Shin ( 2017 ), who stated that IoT is a crucial enabler for MSME innovation. However, the practical implementations of IoT in the MSME context are lacking in the literature. According to Hansen and Bøgh ( 2021 ), MSMEs owners and managers are reluctant to invest in IoT as they are unaware of its usefulness. Moeuf et al. ( 2018 ) and Shin ( 2017 ) called for more studies to provide empirical evidence on the potential of IoT in the context of MSMEs.

IoT implementation and investment in warehouse management of perishable items

By 2025, IoT smart objects are expected to reach 212 billion entities, generating more interest from researchers and practitioners (Salunkhe & Nerkar, 2017 ). In recent years, research on the smart warehouse, logistics, and automation has gained considerable traction, with most studies driven by customer-centric approaches. As automation plays a crucial role in item selection at retail outlets, developing novel IoT implementation strategies in the warehouse is also gaining interest (Kamble et al., 2018a ).

Advances in research on IoT have evolved significantly since 2011, successfully fulfilling Industry 4.0 (Kamble et al., 2020b ). The growth of MSMEs is central to warehousing, given the nature of business (Mogale et al., 2020 ). Hansen and Bøgh ( 2021 ) confirmed that MSMEs struggle to adopt advanced technologies due to a lack of resources, knowledge, dedicated strategies, and practical research implications.

Recently, Kumar et al. ( 2021 ) provided a comprehensive literature review on warehouse management systems through a systematic evolutionary method that considered peer-reviewed articles published between 1990 and 2019. They identified three clusters based on warehouse management themes, sub-themes, and topics. The first cluster (1990–2000) shows that the preliminary studies were published on operation strategy (planning, policy, and warehouse location/size) and warehouse operations (reception, storage, picking, and shipping), while the second cluster (2000–2010) reveals that the primary focus in this period was resource management and infrastructure design (location-allocation/ reallocation, layout design, safety, and ergonomics). The third cluster (2010–2020) focuses on integrating technologies and equipment (sub-theme: technology implementation, automation, control, equipment configuration) and performance evaluation. Concerning the existing literature, Fig. 1 provides information on the chronological development of automation and emerging practices in the targeted area.

Progress in the literature of perishable inventory

The literature is relatively scarce regarding the warehouse management of perishable items (i.e., NIDIs) for MSMEs. Bakker et al. ( 2012 ) discussed various critical NIDI issues that included discount models, the concept of shortages and back-ordering, single item and multi-item inventory control systems, multi-warehouse theory, the need for advanced technologies for deteriorating inventory, multi-echelon inventory control, the concept of inflation, the time value of money, and permissible delays in payment. Bakker et al. ( 2012 ) enhanced the literature by including warehouse and profit aspects. New parameters later evolved in the modeling like inventory policy (FIFO, LIFO), customer service levels, promotions or budget constraints, waste or shrinkage, returns, advances in technology, and product strategy.

At the same time, COVID-19 has shown the need for an advanced warehousing system that is self-sustainable and operational (Kumar et al., 2021 ).

Table Table1 1 presents the application and other aspects of advancement in inventory management, warehousing, and MSMEs. However, the intervention of new technologies such as IoT and blockchain-related issues have not been discussed extensively (Fig. 2 ).

Development in literature in inventory management, warehousing, and MSMEs

IoT integration in the warehouse sector for a perishable inventory model

Not every aspect of the NIDI model can be categorized without the concept of demand and deterioration. Perishable inventory management typically follows price-dependent demand as these commodities are not unique. Customers, therefore, switch to alternative items if prices increase. Bakker et al. ( 2012 ) stated that an item’s price is a key factor that encourages customers to buy more items. They also showed that price-dependent demand is more realistic in the current business environment as lot size and retailer price are mutually interdependent. Tiwari et al. ( 2017 ) studied the impact of price-dependent demand on replenishment strategies with attractive price discounts under the first-in-first-out (FIFO) dispatch policy; seasonal products are generally based on a price-dependent demand function.

Chakraborty et al. ( 2020 ) proposed two static models showing that dynamic pricing can effectively increase overall profit, developing a price-dependent demand-based model with the time value of money. Li et al. ( 2019 ) considered price-dependent demand to explore the possibility of a preservation technology for blackberries, predicting the deterioration period of the items. Pérez et al. ( 2019 ) studied stock-dependent demand using a discounted cash flow approach for inflationary conditions. The present study focuses on a perishable inventory management system for MSMEs, thereby contributing to their strategies and implications.

IoT-based model for NIDI inventory management in the context of MSMEs

According to Čolaković et al. ( 2020 ), a typical IoT network includes four essential layers. The first layer is a sensing layer that includes different types of ‘things’ like RFID tags, sensors, and actuators. Second, the networking layer enables the flow of information through the wired or wireless network. Third, the service layer connects the application by a middleware technology. Finally, the interface layer displays information to retailers and promotes interaction with the system.

In our study, the service and interface layers are together referred to as application and networking layers.

Framework for sensing layer

The design and implementation of sensing layers are crucial for IoT implementation, combined with hardware such as the RFID tag, sensors, and actuators that sense and monitor the physical systems and collect the data (Kamble et al., 2019 ). Yang et al. ( 2019 ) used a network of wireless sensors to collect and transmit information about temperature, humidity, the physical position of items, etc., in real-time to create a smart management system. The general type of sensor includes a temperature sensor, a humidity sensor, and a gas sensor. An actuator is a device that organizes a system and performs actions in an IoT system (Salunkhe & Nerkar, 2017 ). Embedded systems are generally controllers that detect an electrical function with real-time processes (Čolaković et al., 2020 ; Modh et al., 2015 ; Salunkhe & Nerkar, 2017 ; Yang et al., 2019 ).

A protocol is a standard set of rules that allow electronic devices to communicate with each other. The protocols decide the data transmission mode, and commands are based on Bluetooth, RFID, Zing bee, or BLE technology (Čolaković et al., 2020 ).

Framework for networking layer

A gateway is a part of networking hardware used in communication networks that permit data to flow from one node to another. Gateways are distinct from routers or switches in that they communicate using more than one protocol (Salunkhe & Nerkar, 2017 ). Some available gateways include LTE Cellular Gateways, Ethernet Gateways, Cellular Gateway, Wireless sensor adapters, and Modbus Gateway.

Connectivity

Connectivity processes enable the device to communicate from the server and include 3G/4G/5G, Wi-Fi, and White space spectrum.

Connection management platform (CMP)

CMP is an integral part of the networking layer, mainly responsible for connecting the sensing & application and the management layers. The connection management platform includes connectivity analyses and monitoring.

Framework for application and management layer

After successfully implementing the sensing and networking layers, the application and management layer provides the much-required human–machine interface. This layer predicts how much effort is required in the warehouse to maintain an optimal inventory level. The framework is based on the synchronization process, data analytics, and maintenance concepts.

Nunes ( 2008 ) defined the perishability index (PI) of each perishable item on which the operating conditions are determined. The perishability index helps the warehouse operation to retain the appropriate temperature and humidity for a specific type of inventory. Based on the discussion in the previous sections, we put forward an IoT implementation framework for the retailer’s warehouse (See Fig. 3 ).

Technological framework for IoT implementation in the warehouse system

Model formulation

Notations and assumptions.

The following notations were used in the model.

Assumptions

The following assumptions are made.

- (i) Lead time is zero and constant market demand (Tiwari et al., 2017 ).

- (ii) At period 0 , x , there is no deterioration; then the product starts deteriorating at a rate of θ , where X is the random deterioration start time (Yang et al., 2019 ).

- (iii) During the cycle, there is no repair or replacement of spoiled items (Chakraborty et al., 2020 ; Patel & Gor, 2019 ).

- (iv) Yang et al. ( 2019 ) and Li et al. ( 2019 ) developed a mathematical model to implement preservation technologies in inventory management systems. Their model considers preservation cost as a variable. In our model, the total investment cost function is φ, for IoT implementation, and includes the implementation costs related to sensing, networking, and application and management layers. Hence, m φ Is a continuous, concave, increasing function of the retailer’s capital investment φ . Through m 0 = 0 and lim φ → ∞ m φ = 1 . Hence, we assume m ′ φ > 0 , which shows that IoT investment is beneficial, and m ″ φ < 0 , to represent the return of the IoT implementation cost.

- (v) We followed the assumption of Pérez et al. ( 2019 ) according to which demand is partially backlogged, where decreasing function β y (i.e., β ′ y < 0 ) represents a fraction of partially back-ordered demand. According to Dye ( 2013 ), it shows the time duration for the next replenishment cycle which satisfies the condition 0 ≤ β y ≤ 1 with β 0 = 1 o r 0 for all y . According to Patel and Gor ( 2019 ), the value of y decides whether shortages are either lost or wholly backlogged.

- vi. We considered infinite replenishment to reduce complexity (Chakraborty et al., 2020 ; Gupta et al., 2020 ).

- vii. Preservation technologies are functional (Li et al., 2019 ).

We assume that the spoilage of an item starts from any random stage in time x. Consequently, we considered two special cases:

Inventory level when x < t 1

Graphical representation of the stock when x > t 1

Profit functions for cases 1 and 2 are calculated separately and drive the expected average profit from the conditions. We used similar values in both cases in the solution approach, so the model is formulated only once.

The total Investment cost of IoT = Overall cost incurred of sensing layer + Overall cost incurred of networking layer + Overall cost incurred of application and maintenance layer + Hidden implementation cost.

The overall cost of sensing layer = Investment cost of gas sensors + Investment cost of temperature sensors + Investment cost of humidity sensors + Investment cost of actuators + Investment cost of the embedded system + Investment cost of protocol setup.

The total cost incurred of the networking layer = Investment cost of Gateways + Investment cost of Connectivity + Investment cost of connection management.

The overall cost imposed on the application and management layer = investment cost of synchronization + Hidden infrastructure cost.

Therefore, the total investment cost of IoT is given by Eq. 4 , where the limit i = 1 to n defines the number of setups.

Case 1: x ≤ t 1

In case 1, we discussed the change in stock level with zero shortage. The literature review suggests that most previous research assumes a specific period in which no-spoilage occurs since, without any monitoring technology like IoT, standalone preservation mechanisms cannot predict a product’s remaining shelf life. For example, a cold storage refrigeration system retains the freshness of perishable items but cannot precisely predict the point at which the product starts deteriorating (Yang et al., 2019 ). Shin ( 2017 ) argues that IoT helps to monitor and prevent perishable food from spoilage. Recently Yang et al. ( 2019 ) conducted an experimental study on a real-time shelf life estimation with IoT by kinetic food quality models. Technically, it is well proven that IoT can monitor and control aspects of warehouse management systems and offers managers new opportunities and benefits (Čolaković et al., 2020 ).

To identify the managerial implications of IoT implementation, we selected one business cycle, as shown in Fig. 4 . For the analysis, it is more useful to consider a random point from which deterioration will start. We also examined how the implementation of IoT plays a role in optimal inventory level decisions with the variance in the deterioration occurrence over time. In Fig. 4 , we represent the length of the business cycle on the x-axis and the warehouse inventory level on the y-axis; the condition I 1 0 < t < x shows the level of inventory before deterioration starts. After a specific period at a certain point, x deterioration begins over the condition I 1 x < t < t 1 . The proposed IoT-governed preservation mechanism is implemented in the second interval ( x ≤ t ≤ t 1 ) and we investigated whether IoT investment is beneficial for a retailer or not with function m ′ φ > 0 , along with the decision of the IoT investment return with condition m ″ φ < 0 . The condition I 2 t 1 < t < T depicts the level of inventory during the shortage period.

The differential equation represents the change in stock level during the no shortage period.

For the second interval,

Solving the above equation under the boundary condition I 1 = 0 ,

The overall inventory holding cost during the period (0, t 1 ) is given by

The costs incurred during the backlogged period t 1 , T and T - t is queue time for customers who seek the item at the time t t 1 ≤ t ≤ T and waiting for the product till the next replenishment is receive in the warehouse. Therefore, the demand which will be backlogged is a fraction of β T - t and the rest is zero.

The change in stock level during t 1 , T shortage period is expressed by-

Solving the equation at I 2 t 1 = 0 ,

The overall backlogged cost during shortage for the entire period is D c s ∫ t 1 T T - t β T - t d t and the total lost sales cost is c 1 D ∫ t 1 T 1 - β T - t d t , while the total amount of back-ordered and sales quantity is represented by D ∫ t 1 T β T - t d t , D t 1 + D ∫ t 1 T β T - t d t , respectively.

The total output volume is I 1 0 with the back-ordered quantity is:

The overall investment in IoT for the period 0 , T is T φ .

Case 2: t 1 < x

In this case, we have considered the entire inventory ( I 3 0 ≤ t ≤ t 1 ) consumed before the deterioration starts. The inventory consumption pattern is shown in Fig. 5 . For both, the cases expected average profit function is calculated separately.

The variation in the stock level is given by Eq. ( 13 ).

Applying the condition I 3 t 1 = 0 , we obtain Eq. ( 14 )

At a specific period holding cost is given by Eq. ( 15 )

The overall output or quantity of production in the present situation is given by Eq. ( 16 ).

If the shortage and cost of lost sales are not dependent on x they all are identically similar to Case 1. Therefore, the average expected profit is given by Eq. ( 17 ).

For simplification, we have used the approximation method shown in Eq. ( 18 ).

Solution methodology

The objective of this study is to maximize profit through IoT implementation. The profit function is given by Eq. ( 17 ). This type of problem is called a fractional program (FP). We begin by considering the definition of the fractional program.

If the objective function is the ratio of two non-linear functions, then the optimization often presented by programming is called fractional programming (Dubey et al., 2020 ; Vandana et al., 2018 ).

Let us consider function q x , which is the ratio of f x and g x , that helps to solve the concavity of the average profit function. This concavity relates to the rate of change of a function’s derivative, which belongs to set S = x ∈ X : c h x ≤ 0 where g x is positive on X , then in non-linear programming, it will satisfy the sup q x : x ∈ S . Here sup means supremum or large set. So, f x ≥ 0 is concave function and g x > 0 and h x > 0 are convex functions (Cambini & Martein, 2009 ).

We adopted the standard procedure of Cambini and Martein ( 2009 ) to solve the fractional programming problem.

Proposition 4.1

If we perform fractional programming and consider both g x and f x are solved through concave fractional programming, the selective function q x will be pseudo concave on set S. This condition accrues as one of them ( x or g x ) is strictly pseudo-convex, and the other is strictly pseudo concave.

Proposition 4.2

Concave fractional programming provides a set of local maximums. Thus, there will be one global maximum in the set. In this case, we used Karush–Kuhn–Tucker conditions and assume that the value of f x is strictly concave or g x is strictly convex. Karush–Kuhn–Tucker (KKT) is used for non-linear functions in differentiable concave functions for profit maximization.

Note: KKT solves the first derivative test for non-linear programming.

To prove the proposition, we need to show that the total profit function T P t 1 , T , φ is concave.

As g x = x ; where all the values of x show convexity.

Solving Eq. 19 , we got

and ∂ T P ∂ φ = D θ m ′ φ 2 ∫ l t 1 c h x t 1 - x 2 + c t 1 - x 2 f x d x - T 23

The following proposition establishes the concavity of T P t 1 , T , φ for one business cycle with a backlog.

Proposition 4.3

At any value of φ , the profit function T P t 1 , T , φ is indeed concave w.r.t. the length of one business cycle time T and t 1 , so that p - c + c l - c s T - t 1 > 0 ; for all the values of T and t 1 yields.

For any given φ , the second-order partial derivatives of Eq. ( 21 ).

Differentiating Eq. ( 22 ) w.r.t. t 1

The term ∂ 2 T P ∂ T 2 < 0 , because p - c + c l - c s T - t 1 > 0 and β ′ T - t 1 < 0 . Now according to the definition g ′ x > 0 and 0 ≤ m φ < 1 solution will follow ∂ 2 T P ∂ t 1 2 < 0 (Li et al., 2019 ).

The Hessian matrix or Hessian is a square matrix of second-order partial derivatives of a scalar-valued function or scalar field, which describes the local curvature of a function of many variables (Li et al., 2019 ).

Putting the value from Eqs. 25 and 26 in Eq. 28 .

Li et al. ( 2019 ) proposed and proved the lemma on concavity for Hessian matrix solution, according to that if ∂ 2 T P ∂ t 1 ∂ T = ∂ 2 T P ∂ T ∂ t 1 , ∂ 2 T P ∂ T 2 < 0 and ∂ 2 T P ∂ t 2 < 0 then total profit function T P t 1 , T , φ is strictly concave and average profit function i.e. ∇ t 1 , T , φ = T P t 1 , T , φ T will be strictly pseudo-concave which is the complete proof of the proposition.

Proposition 4.4

Investment in IoT is always profitable for the warehouse in MSMEs because it decreases the length of the shortage period, increases the inventory level in the warehouse, and the ratio between t 1 / T i.e., optimal service level improves with the implementation of IoT.

As per the assumptions, T - t 1 is the length in which the warehouse stock level is zero, and 0 , t 1 is the operating period in the cycle 0 , T .

Simplifying Eq. ( 17 ), we get,

Hence, we can say that cycle time T and deterioration starting point t 1 is the function of IoT investment cost φ . By implicit differentiation w.r.t. φ we get,

where a 1 = θ m ′ φ 2 ∫ l t 1 t 1 - x 2 c h x + c f x d x > 0 ,

and a 4 = ∫ t 1 u c h f x d x > 0 .

Solving Eq. ( 33 ) and ( 34 ), we can get

As T > t 1 , d t 1 d φ > 0 , Therefore, the II nd part of the proposition is proved.

Proposition 4.3 and β T - t 1 is a decreasing function.

To prove the Ist part of the proposition, we differentiate t 1 T w.r.t. φ ,

The above results indicate that the service level is directly proportional to φ , so the proposition is entirely true and well-proofed.

Proposition 4.5

Small retailers always try to limit the stock out period. Therefore, the implementation of monitoring and control techniques such as IoT is essential. High investment in IoT implementation is required to optimize the decision variables so that stock in time gets elongated and helps the retailer reduce spoilage and mitigate the extra cost of IoT implementation.

Proposition 4.6

For any given φ , the overall profit per unit time, has a unique global maximum, The profit function T P t 1 , T , φ n + 1 w.r.t. φ n + 1 .

where m ′ ′ φ n + 1 < 0 . , To optimize and solve the profit function t 1 , T , φ n + 1 , we required a special algorithm due to the non-linear feature of the problem(Dubey et al., 2020 ; Dye, 2013 ; Vandana et al., 2018 ). We have followed the solution approach of Tiwari et al. ( 2017 ), who state that analytical methods fail to solve a highly complex problem and require high computational work and analytics. Particle swarm optimization algorithm (PSO) has been used broadly to obtain feasible solutions based on the food-searching activities of birds (Mogale et al., 2020 ; Tiwari et al., 2017 ). We have adopted the PSO technique with a continuous iteration process due to its broader acceptance and applicability in perishable inventory management literature.

Proposition 4.7

For any value of IoT implementation cost φ distributed over time, the overall profit per unit time for a specific time horizon, say n = 4 y e a r s , has a unique global maximum. Hence, the overall implementation cost is distributed in a span of four years.

Regardless of their implementation costs, the investment in IoT systems has a specific financial and economic lifespan. There are various methods to calculate equipment’s economic lifespan, such as the decline balance method, straight-line method, and production units. According to cost accounting standard-16 (CAS-16) which is issued by the council of the institute of cost accountants of India- “Amortization is the systematic allocation of the depreciable amount of an intangible asset over its useful life” (ICMAI, 2017 ). According to CBDT (Central Board of Direct Taxation), notification clarifies that with effect from April 1, 2017, the depreciation rate will range from 15 to 40 for plant and machinery and 40% for computer items (Income tax India, 2019 ). Our model has used the straight-line method for depreciation calculation (Jennings et al., 2001 ).

We know that φ = T o t a l c a p i t a l i n v e n s t m e n t i n I O T i m p l i m e n t a t i o n .

According to the law of depreciation and amortization, we can split the implementation cost over the n years and profit from the implementation in P i = n.

The overall profit is calculated in Eq. 19 for only cycle 1. To see the long-term effect and tangible benefits of IoT implementation, we have assumed eight replenishment cycles for four years, i.e., each year, two replenishments. Hence, the implementation cost is split into four years (Table (Table2 2 ).

Model formulation for investment distributed in 4 years using amortization and depreciation

Where z = depreciation rate and φ 1 , φ 2 , φ 3 , φ 4 represents the change in the values of φ for a four-year term, respectively.

Computational results

Numerical illustration and analysis.

To illustrate our proposed models, we solved one numerical example involving a small food company. We used PSO run on MATLAB on a 1.80 GHz Intel Core i5 with 8 GB of memory RAM computer to solve the problem (Obradovic et al., 2021 ).

To illustrate the model, we assumed the following values:

Replenishment cost per order K = ₹ 120 per order, Retail price = ₹ 35/per unit, Cost of purchase of item = ₹ 20 per unit, Inventory holding cost c h = ₹ 3 per unit/ unit time, Goodwill cost c s = ₹ 4/per unit/per year, Fixed demand per unit time D = 1000, t d = 0:0417, W = 101, c l = ₹ 5/per unit, θ = 0.2, Rate of Backlog is assumed to be β x = e - x . The uniform distributed deterioration rate was U ∼ 0.024 , 0.076 with a standard deviation of 0.013. The reduced deterioration rate is m φ = 1 - e - a φ with simulation coefficient a = 0.02, depending on the percentage change in deterioration rate regarding capital expenditure in IoT implementation.

The Probability density function (PDF) is given by Eq. ( 44 ).

Sensitivity analysis

To explain the robustness of the proposed IoT implementation model in the warehouse and to analyze the impact of the parameters on the desired optimal solution, we performed the sensitivity analysis by changing the model’s operating parameter values within the range of − 30–30%.

The prior literature argues that one of the most common problems faced by agri-food manufacturing MSMEs worldwide is poor inventory management of perishable items (Zhu et al., 2021 ), affecting the profit of smaller companies and threatening their survival. Our study thus draws meaningful insights for MSME managers/owners seeking efficient inventory management using IoT.

To maximize profit ( ∇ ∗ ) inventory managers in MSMEs always try to maintain warehouse stock levels to avoid shortages of items by implementing advanced monitoring and control technology that regulates the preservation of items. The IoT implementation decision is adjusted so that overall profit and other decision variables are not affected. Higher inventory holding costs push small agri-food retailers to decrease their stock level. Thus, a shorter cycle reduces investment in IoT (Fig. 6 a, b). The observation from Table Table3 3 and Fig. 6 c shows that an increment in the inventory-holding cost and a reduction in the IoT implementation cost counter one another so that the overall profit is constant.

Effect of change in the parameter of inventory holding cost on the variables

Sensitivity analysis of critical parameters for a single cycle

Table Table3 3 shows that when the deterioration rate is high, retailers spend more on IoT investment. On the other hand, Fig. 7 proves that cycle time remains unchanged with high investments. Therefore, managers in small agri-food retailers should increase the order size to enhance their profit and invest in technology. As the product cost is directly proportional to the order level, it directly affects the stock in any given period. If the item’s price is high, then the preservation and monitoring technology investment is higher to reduce the deterioration rate. Table Table3 3 shows that the value of the cycle length and the inventory level strongly depends on the value of the simulation coefficient (a). The lower value of the simulation coefficient indicates an insignificant impact of IoT investment on spoilage rate (Fig. 8 ).

Graph between change in IoT investment vs. cycle time vs. change in deceleration rate

Value of simulation coefficient ( a ) over ‘t1’, ‘T’ by Change (%)

According to Fig. 9 , service level (t 1 /T) increases as an increment in standard deviation. Table Table4 4 depicts an increase in total profit after IoT implementation, but it is insignificant as we deployed the overall IoT implementation cost in one cycle. Earlier studies suggest that when the implementation cost is relatively high and imposes long-term benefits over time, the lifecycle costing depends on the price distribution over a certain period and can be calculated through the amortization and depreciation concept (Moon & Phillips 2021 ). To this end, we integrated the concept of amortization and depreciation and built proposition 4.7. Although we initially developed our model for just one cycle (T), it was extended by n number of cycles ( T n ∗ ) and the results are shown in Table Table5 5 .

Service level Vs. standard deviation

Result of the model for one cycle

Maximum expected profit for the four years of the span

The findings show that investment in IoT is likely to be beneficial for small retailers in warehouse management.

Theoretical contributions and implications of the study

Our study investigated the usefulness of IoT implementation in managing warehouses and the inventory of perishable items, especially for MSMEs. We first formulated a practical IoT-based inventory model in retail operations that emphasized the investment cost, which is of utmost importance for MSMEs. We then examined the profitability and impact of IoT investment on inventory management of perishable items. Our findings suggest that a higher holding cost pushes inventory managers in MSMEs to decrease inventory levels, which eventually leads to a shorter cycle length. These benefits lead to increased product shelf-life, demanding more investments in IoT-based preservation technologies. Therefore, low stock-in period and IoT implementation are also reduced due to the short cycle length and longer product shelf-life, requiring more investment in preservation technology and IoT.

On the other hand, a higher deterioration rate prompts managers in MSMEs to invest more in advanced monitoring and preservation technology to maintain their warehouse inventory levels. To alleviate the effect of items’ goodwill cost, managers are advised to spend more on advanced technology to support the stock-in period. We also observed that a higher value of simulation coefficient ‘a’ increases shelf life and reduces shortages. Thus, the threshold value of ‘a’ decides the level of the IoT investment in the warehouse. Our study presents meaningful implications from both a theoretical and a practical perspective.

At the theoretical level, our study is among the first to open the debate on the applicability of IoT in the specific context of MSMEs operating in a critical sector such as food retailing. Indeed, the application of digital technologies such as IoT has long been unsuitable in the context of MSMEs given the many constraints hindering these companies from implementing and leveraging digital capabilities (Kamble et al., 2018a , 2020b ). Our study asserts that, just like large corporations, MSMEs could implement and benefit from IoT. Hence, scholars and researchers could build upon our findings to explore this topic. On the other hand, we use a novel problem formulation for IoT application in warehouse management (Kamble et al., 2020a ) which could be highly useful for researchers seeking to explore and resolve item perishability in warehousing management.

At the managerial level, two critical implications of our study advance the understanding of MSME owners and managers on the relationship between IoT and perishable items inventory management in the context of MSME retailers. First, our study provides practical proof of the feasibility and usefulness of IoT in managing perishable items in the context of small companies. MSME owners/managers need to understand that IoT investment is beneficial, even though it may be costly at the beginning of the implementation process. They should therefore deploy a long-term vision to leverage IoT implementation efficiently. Second, managers of perishable item warehousing need to be aware that preserving high levels of stocks from perishing requires increased investment in new monitoring and control technologies such as IoT. Hence, the implementation of IoT should be regarded as a strategic initiative for its profitability and growth management. It is true that MSMEs, especially in the food supply chain, struggle with the high cost of warehousing and inventory management. However, the implementation of IoT should not be seen as an additional investment but rather as a solution that can drastically reduce the high cost of inventories. Accordingly, we believe this study will help managers better understand how to leverage IoT to solve item perishability in MSMEs.

Conclusion and future research

The advancement in automated monitoring and control technologies in warehouses has led to new opportunities and challenges for retailers in implementing and maintaining their warehouses’ perishable inventories. However, automated monitoring and control technology such as IoT seems more profitable for MSMEs in the retailing sector. To address this issue, we formulated and analyzed IoT implementation costs in the retailer warehouse. The study aimed to investigate the impact of IoT on existing operating parameters (holding cost, selling cost, deterioration rate, shortage cost, goodwill cost, unit purchase cost) and how it can increase the overall profit of retailers by reducing spoilage.

To this end and to examine the feasibility of IoT implementation strategies, we developed two cases (case 1; x ≤ t1 and case 2; t1 < x) and compared their results, which show that IoT implementation increases retailers’ profit margin. With the help of a sensitivity analysis, we also observed that the simulation coefficient, deterioration rate, and selling price significantly impacts profit. Since IoT implementation is a significant budgetary investment, the overall implementation cost can be divided over time. We also looked at a scenario where the implementation cost is divided over a certain timespan, including amortization and depreciation in the model. Our analysis suggests that retailers could gain more profit in upcoming cycles. We analyzed this notion with the help of a digital example.

However, we also need to specify certain technical limitations of our model. First, we only focused on retailer benefits. It would be interesting to analyze the effect of IoT under the impact of demand-dependent carbon emissions. Second, as is frequent in the prior literature, we only considered deterministic demand rates with zero lead time. Our analysis could be extended by adding more realistic conditions such as delays in product availability, non-zero lead time, carbon emission sensitivity demand, and return on investment (ROI).

Moreover, IoT and other technology cannot be implemented on a large scale without government support, conducive policies, and stakeholders’ cooperation. Further, the factor related to cross perishability is also an essential variable in IoT implementation, which requires more explorative studies in the future. Finally, modeling the payback period of IoT investment could be a relevant and insightful addition to this study.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

- Bakker M, Riezebos J, Teunter RH. Review of inventory systems with deterioration since 2001. European Journal of Operational Research. 2012; 221 (2):275–284. doi: 10.1016/j.ejor.2012.03.004. [ CrossRef ] [ Google Scholar ]

- Belhadi A, Touriki FE, El Fezazi S. Benefits of adopting lean production on green performance of SMEs: A case study. Production Planning and Control. 2018; 29 (11):873–894. doi: 10.1080/09537287.2018.1490971. [ CrossRef ] [ Google Scholar ]

- Cambini A, Martein L. Generalized convexity and optimization: Theory and applications. Berlin: Springer; 2009. [ Google Scholar ]

- Chakraborty D, Jana DK, Roy TK. Multi-warehouse partial backlogging inventory system with inflation for non-instantaneous deteriorating multi-item under imprecise environment. Soft Computing. 2020; 24 (19):14471–14490. doi: 10.1007/s00500-020-04800-3. [ CrossRef ] [ Google Scholar ]

- Čolaković, A., Čaušević, S., Kosovac, A., & Muharemović, E. (2020). A review of enabling technologies and solutions for iot based smart warehouse monitoring system. Lecture Notes in Networks and Systems , 128 LNNS, 630–637. 10.1007/978-3-030-46817-0_73

- Dubey, R., Deepmala, & Mishra, V. N. (2020). Higher-order symmetric duality in nondifferentiable multiobjective fractional programming problem over cone contraints. Statistics, Optimization and Information Computing , 8(1), 187–205. 10.19139/soic-2310-5070-601

- Dye CY. The effect of preservation technology investment on a non-instantaneous deteriorating inventory model. Omega (united Kingdom) 2013; 41 (5):872–880. doi: 10.1016/j.omega.2012.11.002. [ CrossRef ] [ Google Scholar ]

- Gupta M, Tiwari S, Jaggi CK. Retailer’s ordering policies for time-varying deteriorating items with partial backlogging and permissible delay in payments in a two-warehouse environment. Annals of Operations Research. 2020; 295 (1):139–161. doi: 10.1007/s10479-020-03673-x. [ CrossRef ] [ Google Scholar ]

- Hansen EB, Bøgh S. Artificial intelligence and internet of things in small and medium-sized enterprises: A survey. Journal of Manufacturing Systems. 2021; 58 :362–372. doi: 10.1016/j.jmsy.2020.08.009. [ CrossRef ] [ Google Scholar ]